As global supply chain dynamics continue to evolve, the heated clothing manufacturing sector is experiencing a significant industrial shift. Vietnam heated clothing manufacturing is on the rise, as the country leverages its strategic location, policy advantages, and manufacturing capabilities. Vietnam is emerging as a key production center for heated apparel following China’s dominance in this space.

Key Drivers Behind the Supply Chain Transformation

Competitive Manufacturing Costs

Vietnam’s labor costs present a compelling advantage over China’s coastal regions, with manufacturing workers earning approximately 60-70% of their Chinese counterparts. For labor-intensive heated clothing assembly operations, this cost differential directly impacts product competitiveness in the global marketplace.

Strategic Trade Policy Benefits

- CPTPP and Trade Agreements: Providing tariff advantages for Vietnamese-manufactured products entering US and European markets

- Foreign Direct Investment Incentives: Substantial support through land use rights, tax exemptions, and investment facilitation

- Infrastructure Development: Continued government investment in industrial parks and port facilities enhancing logistics efficiency

Manufacturing Challenges and Opportunities in Vietnam

Technical Capability Development: The Critical Success Factor

Manufacturing Challenges:

- Heated clothing production requires expertise across textiles, electronics, and materials science, demanding highly skilled technical workers

- Limited local sourcing capabilities for core components including temperature control chips and heating elements

- Quality management systems require substantial time investment to establish and optimize

Growth Opportunities:

- Vietnamese government’s emphasis on vocational technical education supports skilled workforce development

- Foreign investment brings advanced production technologies and management expertise through technology transfer

- Geographic proximity to South Korea and Japan facilitates technical collaboration and knowledge sharing

Supply Chain Ecosystem Evolution

Current Landscape: Vietnam has established a relatively complete supply chain for traditional textile and apparel manufacturing. However, the electronic components required for heated garments still rely heavily on imports. This situation is improving as more upstream suppliers establish operations in the region.

Development Trends:

- Increasing localization rates for electronic components

- Declining logistics and transportation costs

- Emerging industrial cluster effects in key manufacturing regions

Strategic Considerations for Brand Procurement Teams

Balancing Risk Diversification with Cost Optimization

Procurement Strategy Evolution:

- Diversified Manufacturing Portfolio: Moving away from single-source dependencies toward “China Plus Vietnam Plus” strategies

- Supplier Development Programs: Proactive investment in Vietnamese supplier capability building and technical upgrading

- Strategic Partnership Formation: Establishing long-term collaborative relationships with premium factories for joint product development

Quality Assurance System Reconstruction

Critical Focus Areas:

- Developing Vietnam-specific quality standards and testing protocols adapted to local manufacturing conditions

- Enhanced on-site supervision and technical guidance for critical production processes

- Implementing comprehensive traceability systems from raw materials through finished goods

Enhanced Market Responsiveness

Vietnam’s geographic positioning offers closer proximity to Southeast Asian markets compared to traditional Chinese manufacturing bases, providing brands with improved market access for regional expansion. Shorter supply chains also enable faster response to changing consumer demands and market trends.

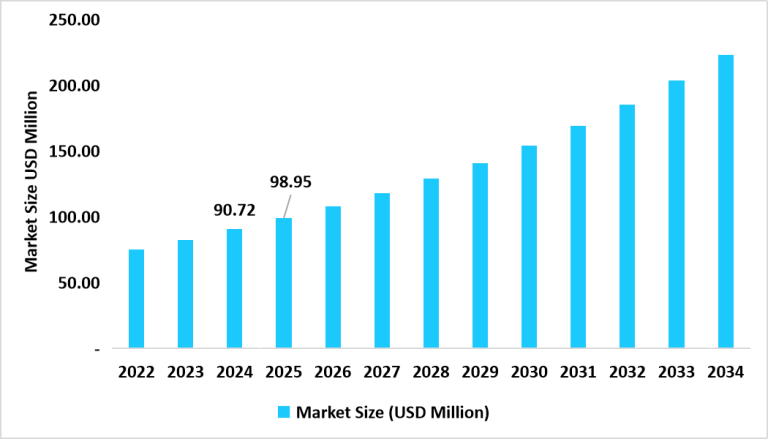

Future Industry Outlook and Growth Projections

Innovation Will Drive Competitive Differentiation

- Local R&D capabilities for smart temperature control technology

- Advanced materials integration in heated apparel applications

- Sustainable manufacturing practices and eco-friendly product design

Industrial Ecosystem Maturation

As more global brands and suppliers establish Vietnam operations, the industry anticipates development of a more sophisticated ecosystem including:

- Specialized technical service providers and consulting firms

- Comprehensive financial and logistics support infrastructure

- Professional talent development and industry knowledge exchange platforms

Regional Integration Acceleration

Vietnam’s RCEP membership positions the country to play an increasingly important role in regional value chain reconstruction, providing expanded opportunities for heated clothing industry long-term growth and market penetration.

Strategic Recommendations for Industry Stakeholders

For Manufacturing Partners: Focus on rapid technical capability enhancement and quality system establishment while building strong relationships with international brands seeking reliable production partners.

For Brand Procurement Teams: Balance cost management objectives with risk mitigation strategies, ensuring sustainable supplier relationships that support long-term business growth and market expansion.

For Industry Development: Collaborative approaches between manufacturers, brands, and government stakeholders will be essential for successful supply chain migration and continued innovation in heated clothing technology.

Conclusion

The migration of heated clothing manufacturing to Vietnam represents more than a simple production base relocation—it’s a strategic response to evolving global supply chain requirements. Success depends on manufacturers’ ability to rapidly develop technical capabilities and establish robust quality systems, while brands must balance cost optimization with effective risk management.

Through collaborative partnerships and shared commitment to excellence, this supply chain transformation can deliver mutual benefits while providing consumers with higher quality, more affordable heated clothing products in the global marketplace.

Views expressed are personal opinions. Industry professionals are welcome to share insights and engage in discussion. Linkedin Whatsapp

#SupplyChainManagement #VietnamManufacturing #HeatedClothing #TextileIndustry #GlobalSourcing #ManufacturingStrategy #IndustrialShift #SupplyChainOptimization #HeatedApparel #ProductionMigration #ManufacturingExcellence #GlobalTrade #ProcurementStrategy #IndustryTrends #SmartTextiles